Plant Based Food and Beverages

With the production of plant-based food and beverages, a residual flow is created. This can be, for example, fiber residues from the production of oat drinks and soy drinks. These residual flows have a high value and can be used as a whole food thanks to the high nutrient content. However, there are major challenges in being able to achieve food quality. These can be microbial challenges because the decay process starts fast, the material itself is sticky and difficult to handle, volume changes in the production process, the nutrient content must not be destroyed or changed and the material must not be burned.

reCirculating Food Dryer enables recycling of the large nutrient flow that comes from the residual flow as well as the utilization of the economic value that the residual product has. From reCirculating Food Dryer, a dried product is delivered during a hygienic process adapted to plant-based food and beverage processes to achieve food quality. The end product becomes storable and can then serve as a raw material for the next step in the processing process.

With reCirculating Food Dryer the result is:

- A dried storable product with food quality

- Recovery of important nutrients

- Reuse results in reduced:

- Carbon dioxide emissions

- Extraction of raw materials from agriculture

- Transports

- Achieve a new raw material with the possibility of further processing

- Protein extraction

- Food production

- Feed production

- Fish feed production

- Integration in the business

- More opportunities for economically and environmentally sustainable marketing of the product

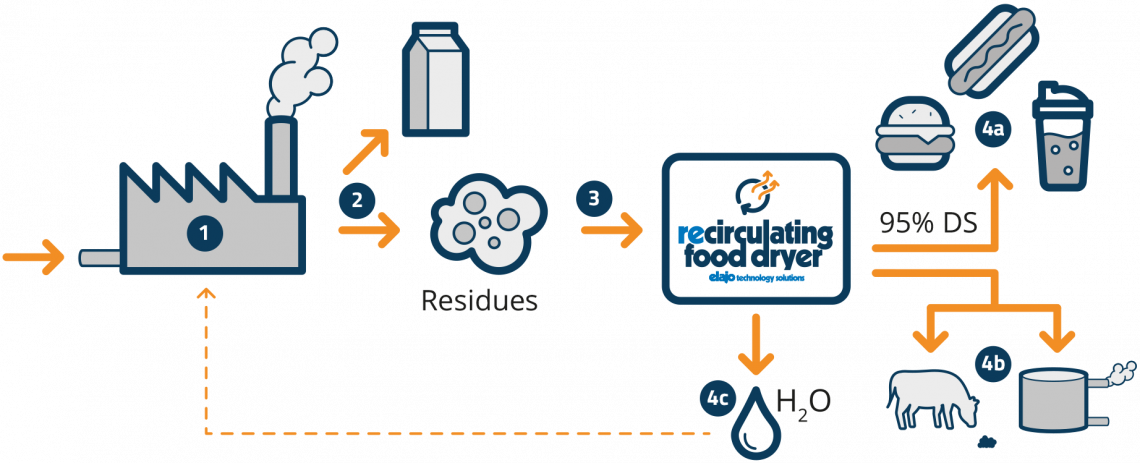

The process, with and without reCirculating Food Dryer

The food/drink is produced

The food product, for example oat or soy beverage, and the residual product in the form of wet oat fiber, okara or brewery's spent grain are obtained

The oat fiber/okara/brewery's spent grain is dried in reCorculating Food Dryer to a dry solid content of 95%

With the dried oat fiber/okara/brewery's spent grain new products can be creataed. For example meat substitute for burgers and hot dogs, fiber rich bread or complement in health food. We have chosen to call the oat fiber product reOAT as it is a durable new oat product.

The dried product can still be used as feed or for biogas production.

The water that is evaporated can be condensed and returned to the process for water recirculation.

More about how reCirculating Food Dryer makes a difference in plant-based food production

From the production of plant-based food and drink, a residual product with a high intrinsic value is formed. ReCirculating Food Dryer can play a crucial role in this process. A challenge with the residual product is that it is short-lived, ie it rots quickly if it is not taken care of care of in an integrated process . reCiculating Food Dryer can be used to stop the rotting process by drying to a high dry solid content which means that the water activity in the material is so low that microbial activity stops. This results in a product that is easy to store and can be reused into a valuable product and that is also easy to transport thanks to a smaller volume and weight.

Analyzes after the drying process show that nutrients, energy, protein and enzymes in the dried material remain. The nutritional values per 100 grams also increase as only water has been removed from the material. This is because low temperatures in the material are ensured so that it is not burned or damaged in any other way. This is of course something that is tested at customer level before each project to ensure the content of the product.

reCirculating Food Dryer can be integrated with plant based food and beverage production and take advantage of the low-value residual heat that often occurs. This keeps energy use down considerably and also takes advantage of energy that would otherwise be wasted. This reduces the environmental impact, which is in line with the commitments to sustainability.

reOAT

Oat beverage production has increased sharply in the world and with it also wet residual products of oat fiber. The residual products hold between 60-75% water. Although the oats has been used for the manufacture of beverages, there are still a lot of nutrients such as fiber and protein left. It is therefore important to take advantage of these and preferably return them to the food chain. We have chosen to call this by-product reOAT! Now large amounts of reOAt are used undried as feed for animals or for biogas production, but if reOAT is dried, it can be used in food production as a complement in different types of food, which can reduce the extraction of raw oats. Today, there is no ready-made solution for drying reOAT and using it for food quality. We have solved this with reCirculating Food Dryer! Of course, the dried reOAT can also be used for dried animal and fish feed. This is the beauty of a stable dried material, it lasts longer, opens up more areas of use and has a higher value.

Okara/Soja

Okara is a by-product that is formed during the production of, for example, soy milk and tofu. Okara has a high nutrient content and can be used for food, such as veggie burgers, feed for livestock and pets, but can also be used as fertilizer in agriculture as the nitrogen content is high. A challenge today is to take advantage of the okara before it rots as its high nutrient and moisture content makes the decay process very fast.

With reCirculating Food Dryer, decay can be avoided as a high dry matter content is obtained after the drying process. A low water activity levels become crucial to keep the product free of microbial activity and store it over time. This means that the okara can be stored and stored for a longer period of time and streamlines transport.

Brewer’s spent grain

Brewer’s spent gran (BSG) is a by-product of the production of beer. The BSG contains several nutrients, especially protein and fiber. Due to the poor durability of the material, many of these nutrients are wasted. If it is dried, the putrefaction process stops and the BSG can be taken care of. Due to the high content of protein and fiber, there are several attractive opportunities to use the BSG in the food industry. Today, it can be used mainly as, for example, feed for animals or biogas.

The BSG could also be used as fertilizer for cultivation. The high protein content results in good nitrogen availability.

With a reCirculating Food Dryer, the BSG can be dried before it starts to rot and can thus be used and reused. Dried BSG could replace flour in several food products and thus get a high-fiber additive. This could be done for, for example, pasta, bread, pie dough, pizza, noodles, bars and snacks, cakes and pastries and more! It could also be used as a high-fiber base in smoothies and shakes.

Plant Based Food and Beverages

reCirculating Food Dryer can be used to dry several different residues from plant-based foods and beverages (PBFB), not just those described above. Residues from PBFB production that are dried can be used in new food products or on animal feed products as raw material that are sent for further processing. Usually, the residue has a lot of nutrients left and has been concentrated and therefore a new valueable product with a long shelf life is created.

The residues normally have a very high water content, which makes them difficult to dry. With reCirculating Food Dryer, you can feed the wet residual product directly and start drying without the risk of the residue rotting or that nutrients are adversely affected.

The traditional methods of drying residual flows are very energy intensive. With reCirculating Food Dryer, the energy use for drying can be greatly reduced while the quality of the end product increases. reCirculating Food Dryer maintains a high hygienic standard, which makes the end product safe.

reCirculating Food Dryer is delivered in accordance with specific food and safty requirements

reCirculating Food Dryer is delivered in accordance with specific requirements in ISO 22000 in ISO 9001. Elajo has extensive experience of working with high requirements as several projects have been implemented in the nuclear power sector. A reCirculating Food Dryer aimed at food is manufactured in accordance with documented safety systems throughout the process. According to these standards, Elajo also ensures that suppliers meet international quality, safety and reliability standards, where it is ensured that their value chain has safe environments and they also meet the requirements of the standard.